It's basically just me doing the electronics design here, though, so not sure how well it would translate to a larger shop. doing it this way we also don't mess up each others libraries. altium detects live that the intlib has changed and reloads it ( no need to restart ) so changes are immediate. the intlibs are stored in a shared folder on the server. you can do this with as many people as you want. whenever he edits his sourcefiles the am_library gets updated so i immediately have the updated part. that means i have loaded vh_library.intlib and am_library.intlib i own the sources to vh_library, he has the sources to am_library. we use each others integrated library, but we only edit our own source library.

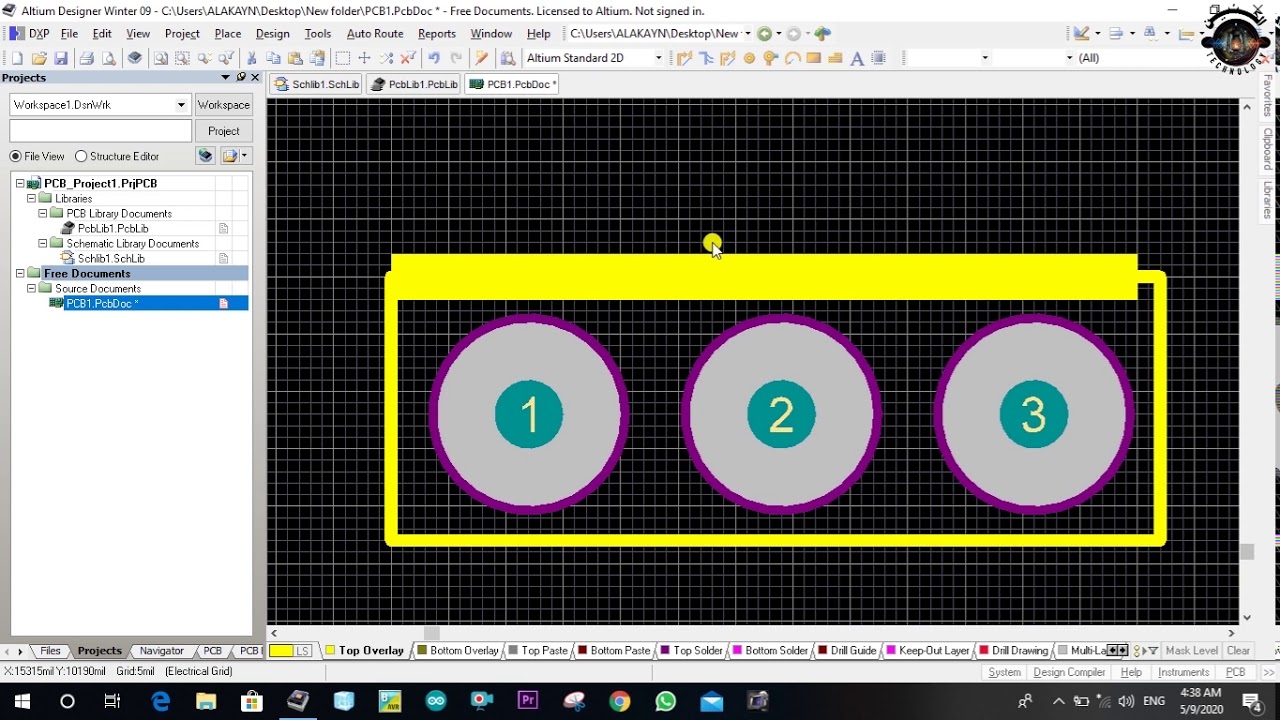

so whenever i make a footprint or symbol i simply edit them in the individual document, link em and hit 'compile'. that one is loaded as the main library in schematic and pcb. resistors 0805 resistors 0603 capacitors 0805 mechanicals, transistor footprints, ic footprints, etc the whole project gets compiled into 1 integrated library. as well as tens of pcb library documents.

resitor smd, resistor thru-hole, transisot rsmd, transistor thru hole, analog, digital, capacitro smd, capacitor thru hole, mechanicals, etc. inside this project are tens of schematic library files. I have a project for an integrated library. Altium's solution seems to limit this to inside one organisation, which negates any real advantage. In some ways I do see the benefits of using cloud computing for doing component footprint management, but for me the benefit would be getting a community of users to build up good footprints and symbols for common parts and validate their use (like the included libraries, but with user participation). I guess one solution to the latter might be to build up a 'multicomp' library for some of the more common parts with multiple suppliers. This just ends up with me not bothering to be consistent and having a very manual labour intensive BOM generation process. The other issue I end up with is more subtle, for some parts I have a generic sheet symbol / footprint, and a value tag, such as semi passives, which becomes a pain in the ass at BOM time, and other parts such as connectors where there are multiple suppliers but I have modelled the sheet entity/footprint labelled for one supplier, and have to change schematics to get a correct BOM despite the board not really changing. Dave I share your frustration in this regard, I keep finding myself having to remember what project I last used an obscure part in, then go dig out the library and copy the footprint to the current project.

0 kommentar(er)

0 kommentar(er)